A new way to power EVs

If you think Detroit automakers are laggards in offering electric vehicles (EVs), guess again. General Motors is currently leading the pack, offering the Cadillac Celestiq, Cadillac Escalade IQ, Cadillac Lyriq, Cadillac Lyriq-V, Cadillac Optiq, Cadillac Vistiq, Chevrolet Blazer EV, Chevrolet Equinox EV, Chevrolet Silverado EV, GMC Hummer EV Pickup, GMC Hummer EV SUV, and GMC Sierra EV, all of which are fueled by electrons, not petroleum.

GM

General Motors and LG Energy Solution are developing lithium manganese-rich prismatic battery cells, or LMRs, for use in future GM vehicles. GM plans to be the first automaker to use LMR batteries in its EVs beginning in 2028. The breakthrough battery chemistry will allow for electric vehicle (EV) batteries that are 30% more energy dense than current ones, yet cost the same as the lithium iron phosphate batteries, or LFPs, currently in use.

“We’re excited to introduce the first-ever LMR prismatic cells for EVs, the culmination of our decades-long research and investment in the technology,” said Wonjoon Suh, executive vice-president and head of the Advanced Automotive Battery division at LG Energy Solution. “GM’s future trucks powered by this new chemistry are a strong example of our shared commitment.”

The announcement follows a similar one made by Charles Poon, Director of Electrified Propulsion Engineering at Ford, on April 23rd. “This isn’t just a lab experiment. We’re actively working to scale LMR cell chemistry and integrate them into our future vehicle lineup within this decade.”

Poon cited the LMR batteries’ lower production cost, higher energy density, enhanced stability and safety as key factors in their superiority. Ford started their EV offerings with nickel-cobalt-manganese (NCM) batteries, later adding lithium-iron-phosphate (LFP) batteries in 2023.

How LMR batteries differ

To understand how these batteries differ from those currently in use, you must understand how a battery works. Simply put, electricity is produced in a battery from a reaction between the anode, which creates electrons, and a reaction in the cathode, which absorbs them. Electrolytes allow the electric charge to flow between the cathode and the anode. The net product is electricity.

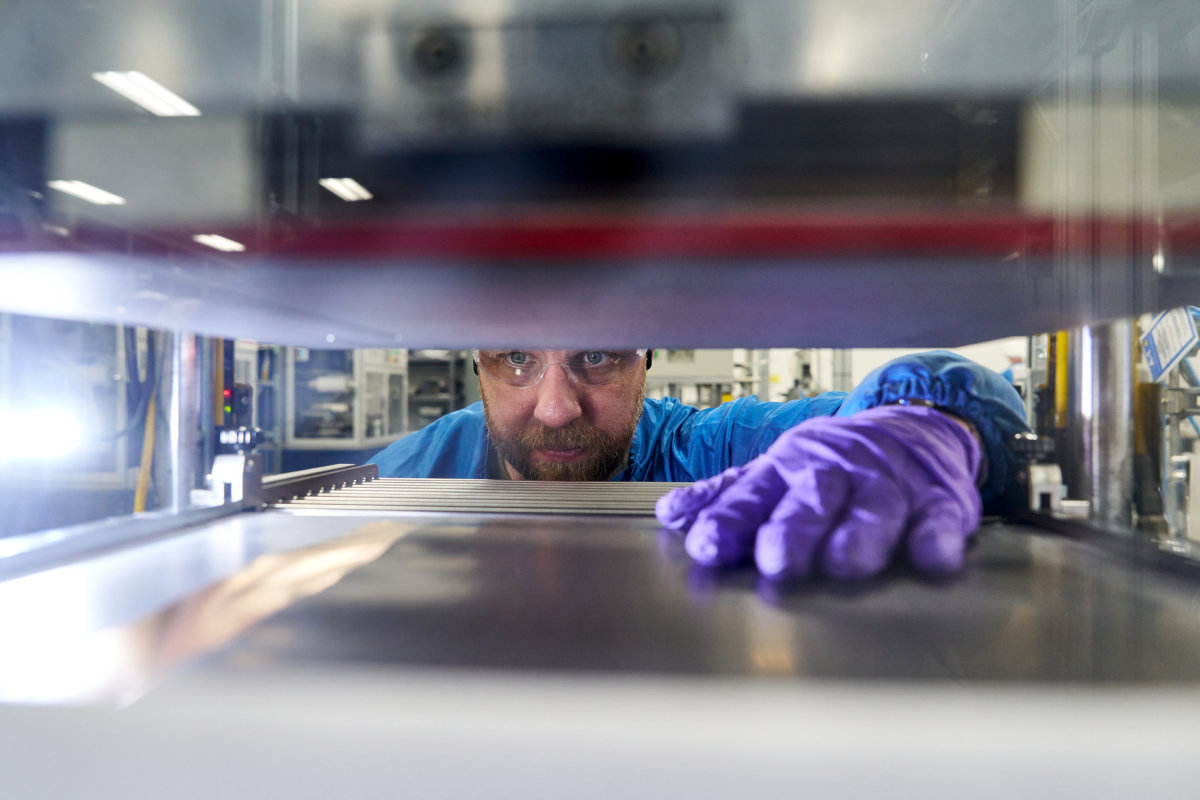

Photo by Steve Fecht for General Motors

GM’s Ultium platform currently employs nickel manganese cobalt aluminum oxide batteries, also known as NCM, which uses 85% nickel, 5% cobalt, and 10% manganese for its cathode coating. However, cobalt and nickel are expensive, and cobalt is known to be mined with child labor, which is a human rights concern. Another widely used battery chemistry is lithium iron phosphate, or LFP, which costs about 20% less than an NCM battery, but China has a near monopoly in LFP cell manufacturing, according to S&P Global.

GM

In contrast, LMR batteries use roughly 35% nickel, 65% manganese, and virtually no cobalt. Given that it’s the fifth most common element on Earth and widely available, manganese is far less expensive than nickel and cobalt. LMR batteries cost roughly the same to produce as LFP batteries, while being 33% more energy dense. GM plans to produce rectangular prismatic cells rather than the pouch cells currently being used, enhancing the packaging efficiency and reducing the number of components by as much as 75%. Additionally, LMR chemistry works well with bigger cell sizes, which lowers system costs even more.

While the Chevrolet Silverado EV Work Truck with Max Range has an EPA-rated range of 492 miles, it uses an NCM battery. Using an LMR battery would allow GM to deliver similar range and lower the price, which now starts at $57,095 and tops out at $97,895.

Final thoughts

While GM began researching manganese-rich lithium-ion battery cells in 2015, performance and durability haven’t been up to par. Historically, they’ve suffered from a short lifespan, losing voltage in a short period of time, but GM and LG Energy Solution state that they have overcome such obstacles by “adding proprietary dopants and coatings, along with particle engineering, process innovations, to achieve the right energy density and arrangement of battery materials inside the cell to keep them stable,” according to a GM press release. The research and development at GM’s Wallace Battery Cell Innovation Center in Warren, Michigan, has led to the corporate partners holding more than 200 patents around the world on LMR-related technology.

GM

Ultimately, GM sees the technology providing more range at a lower cost, which should help bring down the cost of EVs, a sticking point in their journey towards being more widely accepted. According to Cox Automotive, the average price paid for a new car in March 2025 was $47,462. By comparison, the average price paid for an electric car was $59,205 – a 22% price premium and the highest in a couple of years. Such price realities are driving the research to reduce battery costs, while tariffs are pushing automakers to rely less on China for their minerals and components.